GENERAL OVERVIEW

For over 20 years, my research has been directed at the synthesis, characterization, and testing of catalysts for numerous applications related to energy and the environment. These include:

1. the conversion of syngas (COX and H2) derived from natural gas, coal, and biomass to hydrocarbons that are upgraded to transportation fuels and chemicals;

2. the production and purification of hydrogen for fuel cells;

3. the selective reforming of light alkanes to chemical feedstocks for the petrochemicals industry;

4. the hydrodeoxygenation of oxygenates derived from biomass pyrolysis to high octane products.

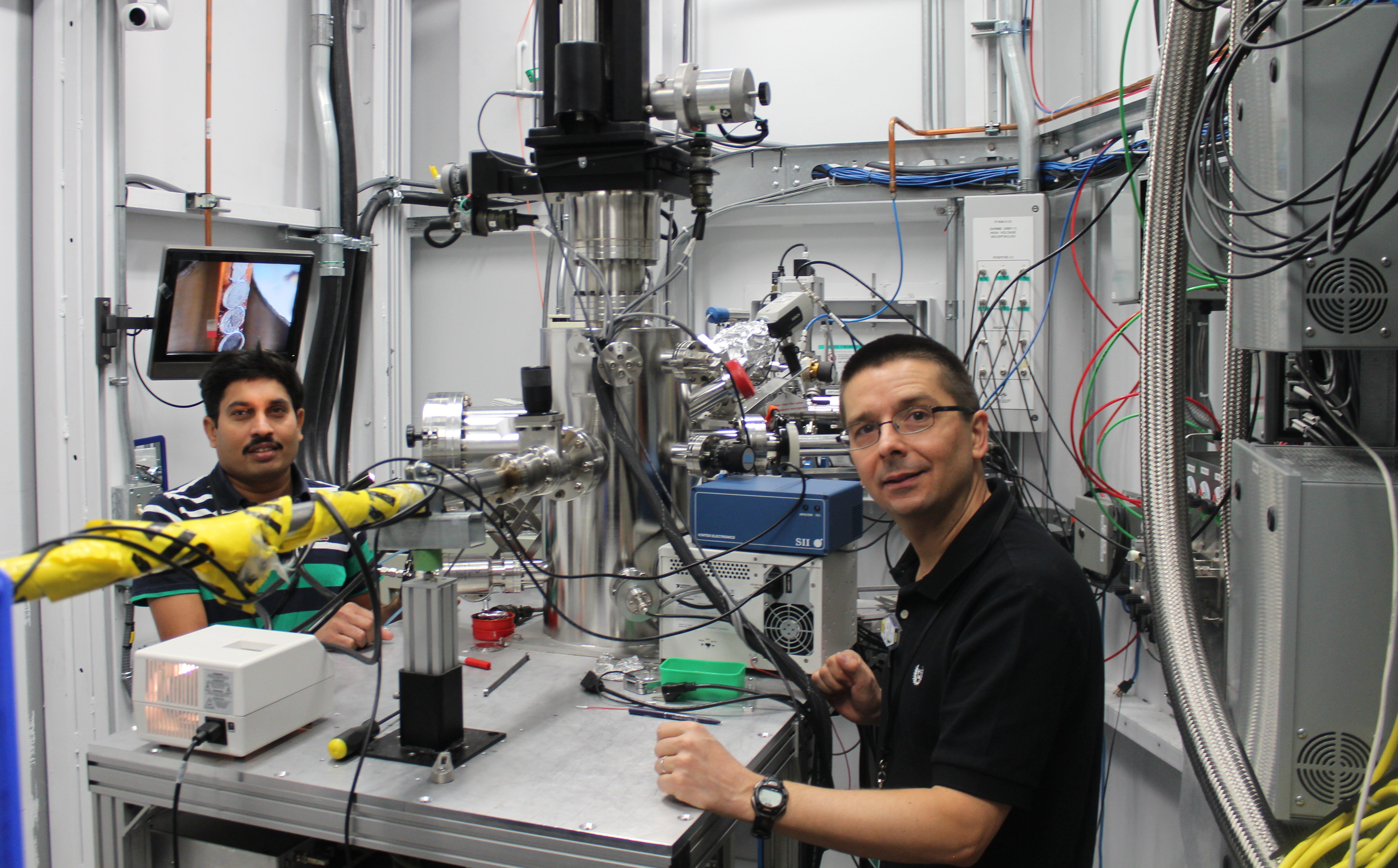

My goal is to continue in these areas, and expand to related ones. Ongoing threads are using synchrotron radiation for the characterization of catalysts, promoters, supports, and poisons; applying isotopic tracers to shed light on reaction mechanisms; and practical applications of nanotechnology.

Saskatoon, Canada

Saskatoon, Canada

Fischer-Tropsch synthesis

Texas is a leading producer of natural gas in the country. Since 2000, shale gas has become the key source of natural gas and production has risen sharply (e.g., 6 time between 2007 and 2013). In Texas, top producing fields include Newark East Barnett Shale (~2 trillion cu. ft per year), Haynesville Shale (~1.5 trillion cu. ft per year), Eagle Ford Formation (~1 trillion cu. ft per year), Carthage (~650 billion cu. ft per year), and Sprayberry (~300 billion cu. ft per year). While the lion’s share of natural gas is used to generate electricity, some is used to power vehicles. The problem is that it has few retail outlets. A better way to monetize natural gas is to first convert it to syngas (CO and H2) using a combination of steam reforming and partial oxidation known as autothermal reforming. Fischer-Tropsch synthesis (FTS) with either cobalt (preferred) or iron catalyst converts the syngas to hydrocarbons: 2H2 + CO → -[CH2]n– + H2O (ΔH = -167 kJ/mol).

In general, syngas (CO + H2) can be derived from natural gas, coal, and biomass and converted to hydrocarbons and oxygenates that are upgraded to transportation fuels and chemicals. Often, the terms GTL (gas-to-liquids), CTL (coal-to-liquids), BTL (biomass-to-liquids), and XTL (any resource-to-liquids) are employed. While high temperature FTS relies on fluidized bed reactors and is targeted to gasoline range hydrocarbons, my attention is on the more environmentally benign low temperature process (200 – 230oC), which targets longer chain hydrocarbons with high cetane number (related to ignition delay time). These premium products are upgraded to ultrapure, virtually sulfur-free, diesel and jet fuels, as well as lubricants and food grade waxes.

There are numerous challenges to be overcome for improving FTS catalyst formulations. Small nanosized cobalt clusters (2 – 4 nm) are especially susceptible to oxidation and encapsulation by the support by intrinsic or externally added steam, and as H2O is a major product, oxidation is typically problematic above 80% conversion for typical catalysts. Oxidized cobalt is active for water-gas shift, CO + H2O → CO2 + H2, which tends to increase CO2 and drive up the selectivity of undesired CH4, a greenhouse gas. This is due to enhanced chain termination caused by the higher surface fugacity of hydrogen. Water also accelerates sintering due to surface oxidation-reduction cycles. Other causes of deactivation of FTS catalysts include the buildup of carbonaceous deposits and poisoning by impurities from natural gas (e.g., H2S, COS), coal and biomass (e.g., H2S, NH3 and other nitrogen compounds, hydrohalic acids, alkali compounds, and various metals). Therefore, my research is centered on new catalysts to optimize cobalt size and morphology, interactions with the support, reducibility, and resistance to deactivation.

New small channel and microchannel reactors require new catalyst designs. For example, novel compact heat exchange reactors offer both high single pass conversion (like a fixed bed reactor) with excellent heat management (like a slurry reactor). However, pellets are utilized to prevent a large pressure drop from occurring. One problem with supporting cobalt nanoparticles within the pores of pellets is that hydrogen diffuses more rapidly than CO. This results in higher H2/CO ratios on the catalyst surface, which in turn drives up selectivity to CH4, a greenhouse gas, at the expense of valuable C5+. My research is focused on new catalysts with optimal pore characteristics for maximizing C5+ selectivity and driving down light gas selectivities that deviate above the ASF kinetics curve.

Hydrogen production

Fuel cells for transportation and portable power applications offer the potential for eliminating line sources of unwanted emissions (CO2, NOX, SOX, particulates, etc.). However, the costs of fuel cell vehicles (one order of magnitude) and hydrogen production (factor of 4) are too high. Syngas produced from natural gas is an attractive route for generating hydrogen, but the catalysts in polymer electrolyte membrane fuel cells are susceptible to poisoning by CO. My research aims at converting CO and generating additional H2, as well as purifying the hydrogen, by using the low temperature water-gas shift and preferential oxidation (PROX) reactions. The catalysis relies on a junction between the metal and active support (e.g., ceria, zirconia, ceria-zirconia, etc.) either through a support-mediated redox mechanism or an associative mechanism. The defects in the oxide provide sites for activating water, while the metal facilitates hydrogen transfer pathways. I have worked extensively with Honda Research Inc. to demonstrate with isotopic tracers that additives such as light alkali promoters (e.g., Na) facilitate scission of the C-H bond in reactive formate intermediates that significantly accelerate the reaction rate. I have recently demonstrated that the catalysts can also be used to accelerate formate decomposition in releasing H2 from potential chemical carriers, such as formic acid and methanol.

Bioethanol may be an important source of hydrogen in the future, and I have a fruitful collaboration with INT in Brazil in this area. The catalysts are comprised of active oxide carriers and metal particles. However, one critical difference is that the metals chosen must have the capability of handling carbon-carbon scission reactions (e.g., supported Co and Ni catalysts).

CO2 conversion

There is growing evidence that anthropogenic CO2 is linked to climate change. One way to convert CO2 is to first capture it at a point source (e.g., power plant) and then use FTS technology. However, in that case, H2 must be from sources that do not generate CO2 (e.g., solar or nuclear powered electrolysis, direct methane decomposition, etc.). My research investigates new catalysts that rely on a reactive interface between FTS metals (Co, Fe, Ru) and an active support (e.g., ceria) for converting CO2 to useful products, like alcohols and olefins. Here, the catalysis relies on both reverse water gas shift, CO2 + H2 = CO + H2O and FTS. Defects in the support promote WGS/RWGS pathways by providing sites for activating water.

Reforming

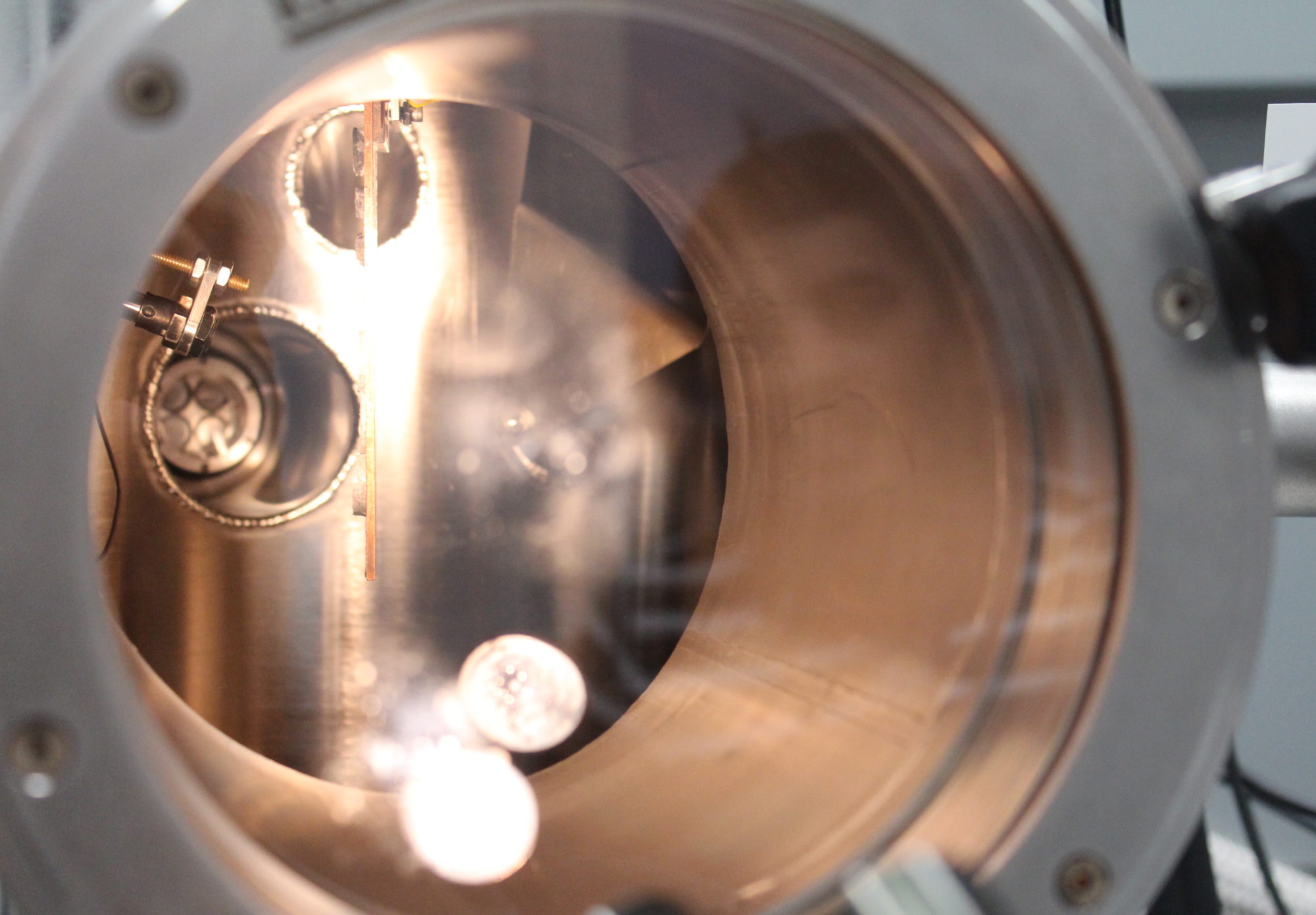

I currently have a collaboration in this area with a major oil company in Texas. Aromatization of light alkanes (e.g., C6-C8) to benzene, toluene, xylene, and ethylbenzene is important to provide feedstocks for the chemicals industry. Benzene alone is critically important for making plastics, resins, pharmaceuticals, detergents, and a host of other important products. My research in this area is focused on KL zeolite (uniaxial with 7 angstrom narrow window and 13 angstrom lobes) supported highly dispersed Pt clusters. The isotopic tracer studies have shown that a 1,6 ring closure mechanism likely occurs. These catalysts are highly susceptible to poisoning by sulfur. Using a special low energy beamline at the Canadian Light Source, Inc., we found that sulfur poisoning occurs in part by direct adsorption, which breaks up ensembles of platinum required for aromatization, resulting in higher selectivities to the less structurally sensitive dehydrogenation reaction (requires 1 to 2 atoms). My research is focused on nanostructuring techniques (e.g., simplified chemical vapor deposition methods) and promoters that improve the resistance of Pt to sulfur through “gettering” and anchoring.

Saskatoon, Canada

Saskatoon, Canada

Hydrodeoxygenation

One significant problem with biofuels from pyrolysis is that the molecules contain oxygen. This reduces their heating value (they are essentially partially combusted) and makes them corrosive and unstable for storage. Using phenol as a platform molecule, my research using infrared spectroscopy has provided evidence that oxophilicity of the catalyst support for palladium particles is critically important. Oxophilic supports such as zirconia and niobia tend to adsorb the keto-tautomer of phenol on the surface via the oxygen atom, allowing for hydrogenation of the carbonyl function in lieu of the ring. The dienol molecule formed is readily dehydrated to benzene, the target product of interest. New catalysts are underway that maximize the density of oxophilic sites. This research is in collaboration with INT in Brazil and the University of Oklahoma.